Metal Extrusion

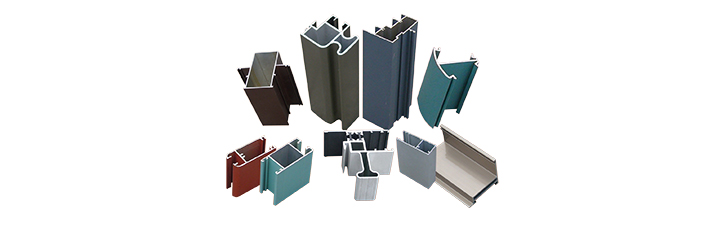

At MES the Aluminum Extrusion is our specialty process. It is most suited for large-volume production of parts. We have access to a variety of presses in sizes ranging from 6 to 14 inches, which can produce different profiles, shapes, and forms. Our aluminum extrusion services are commonly employed in industrial, architectural, residential, transportation, consumer, marine, and electrical sectors.

- Our aluminum extrusion process produces identical, elongated parts with uniform cross-sections.

- Parts with a wrought structure and relatively tight dimensional control can be produced to Aluminum Association of America standards.

- Our presses produce aluminum parts of different shapes, weighing from 0.15 to 35.0 pounds per foot.

- Non Ferrous extrusion services offer benefits such as greater design flexibility, easy fabrication, low tooling cost, precise tolerance, and short lead time.

- Aluminum parts produced using the extrusion process offer an environment friendly solution compared to those produced using other methods.

- Parts produced using the aluminum extrusion process exhibit high strength-to-weight ratio and corrosion resistance.

- Molded Extruded Specialties offers Impact Extrusion as well as other extrusion alternatives.

Molded Extruded Specialties offers a full compliment of secondary services to Aluminum Extruded Parts:

- Powder Coating

- CNC Services

- Anodizing

- Packaging

- Welding

- Stretch Forming

- Tapping

- Wet Paint

- Punching

- Bending

- High Tolerance Cutting

- Black Oxcide

- Stamping

- Drilling

- Deburring

- Shearing

- Swiss Milling

- Lighting

- Aluminum Railings, Panels and Frames